Rifle barrels vary based on material, profile, and even the type of rifling. This guide is going to explain the differences between these gun barrel options and help you choose the best barrel for your setup. Whether you're looking for an AR15 barrel or want to upgrade your benchrest bolt-action, you’ll learn the key differences of these rifle parts in this guide.![]()

What Materials Are Rifle Barrels Made Of?

The main component used to make a rifle barrel is steel because steel can withstand the heat and wear of bullets being fired down them. Popular types of steel alloy used for rifle barrels are Chromium and Molybdenum which are used to produce Chrome-Moly barrels. These barrels are more cost-effective to produce and are strong enough to handle the wear of different cartridges. Another popular barrel material is stainless steel. Stainless steel is stronger than Chrome-Moly and is more resistant to heat and corrosion than non-stainless steel barrels. This is why many hunting and competition rifles use stainless steel. However, stainless steel barrels cost more to produce than other steel barrels.

Another type of barrel material that is becoming more popular is carbon fiber barrels. Carbon fiber barrels are not completely made of carbon fiber. Instead, these barrels are thin steel barrels that are then wrapped in carbon fiber. The benefit of a carbon fiber-wrapped barrel is that it allows for the same stiffness as a steel barrel and better heat dispersion while being significantly lighter than a steel barrel of the same diameter. These types of barrels are very popular among hunters who may be hiking a lot, where the weight of their rifle is very important. Competition shooters also use carbon fiber barrels because the rapid heat dispersion allows for more accurate and consistent shots when firing rapid courses of fire. The downside to carbon fiber rifle barrels is that they tend to cost more than standard steel barrels, including stainless steel barrels.

What Is Rifling in a Gun?

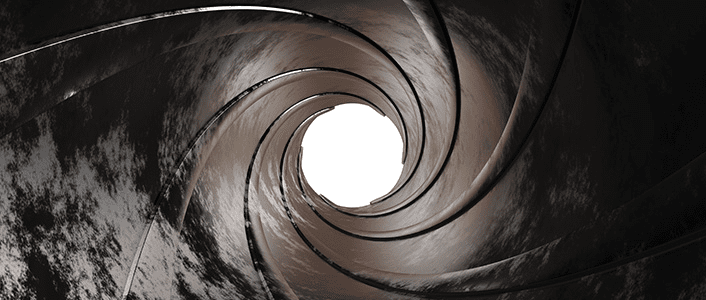

Barrels have grooves cut in a spiral motion down the middle of them called rifling, which is where the name "rifle" comes from. The rifling of a barrel is what comes in contact with the bullet as it travels down the barrel and spins it to make it stabilize as it leaves the barrel. There are different methods to create rifling in a barrel.

Barrels have grooves cut in a spiral motion down the middle of them called rifling, which is where the name "rifle" comes from. The rifling of a barrel is what comes in contact with the bullet as it travels down the barrel and spins it to make it stabilize as it leaves the barrel. There are different methods to create rifling in a barrel.

The most common methods are:

- Button Rifling

- Hammer Forging

- Cut Rifling

What Is Rifle Barrel Twist Rate?

The twist rate of a barrel is the term used to describe how fast the rifling rotates the bullet when it is traveling down the barrel. The twist rate is described as a ratio that tells you how many rotations the bullet undergoes within a certain length given in inches. For example, the twist rate of 1:8 signifies the bullet rotates one time in eight inches. The lower the second number, the faster the twist rate; the higher the second number, the slower the twist rate. The twist rate is important because it determines how well a bullet is stabilized when it leaves the barrel.

If a bullet is not stabilized as it leaves the barrel, it will begin to "wobble" or "tumble" mid-flight and affect accuracy and performance. Twist rates of barrels are determined by the caliber/cartridge the barrel is chambered in, but since projectile weights can vary, barrels of the same caliber are often available in several different twist rates. Heavier caliber bullets will need a faster twist rate in order to stabilize the bullet before it leaves the barrel. Lighter bullets will need a longer twist rate in order to stabilize.

Button Rifling is a process in which a button is pushed through a barrel to imprint the rifling of the barrel. The button is the shape of the bullet that the barrel is chambered in, and as it is forced through the barrel, it leaves behind the grooves of the rifling with the twist rate of that barrel. The benefit of this process is that it is consistent and repeatable while keeping costs down. This allows mass production of barrels, allowing shooters to purchase them at a lower cost. The downside is that this process requires an additional stress-relieving process afterward.

Cut Rifling is a process where a blade is rotated down the center of a barrel to remove steel to form the rifling of the barrel. There are a couple of different ways this can be done. Single Point Cutting is when one blade is passed through the center of the barrel multiple times to cut the rifling. Broach Rifling is when a tool with multiple blades is passed through the barrel to cut multiple grooves at once, requiring this process only to be done once. The benefit of the cut rifling process is the precision at which the rifling can be cut and changed if needed. However, this process is slower and costs more money due to the time it takes to have precise and consistent rifling.

Cold Hammer Forging is another manufacturing procedure. This process is done by repeatedly hammering the barrel in a uniform pattern. While the barrel is being hammered, there is a metal rod inside the barrel that forms the rifling. As the barrel is hammered, the rifling is pressed into the inside of the barrel. This process is repeated until the desired length and proper specifications of the barrel are met. This process also makes the barrel steel stronger due to the repeated hammer down on the barrel metal.

What Do Rifle Barrel Profiles and Contours Mean?

Barrels come in all different contours and thicknesses. Barrel profiles or contours are determined by the primary use of the rifle and provide various benefits. There are many different barrel contours, but they can be broken down into three main groups:

- Lightweight

- Medium

- Heavy Profile

Lightweight contour barrels are thin and consist of profiles such as pencil or sporter profile barrels. The primary reason someone would want a lightweight barrel is to cut down on the weight of the rifle. This is useful when you are doing a lot of maneuvering or hiking with a rifle, and every bit of weight has an impact on how well you move. Sporter contour barrels are the most common of the lightweight profile barrels and are very popular on general use and hunting rifles. These contour barrels provide a more rigid barrel than a pencil profile barrel while still maintaining a manageable weight.

Medium-profile barrels are a step up in thickness from the sporter contour barrels. These barrels provide a balance between lightweight barrels and heavy barrels. The benefit of the thicker barrel is that it prevents the barrel from heating up quickly when firing consecutive shots. As the barrel heats up, the bullets become less consistent in their grouping on the target. The tradeoff is a heavier barrel, which increases the overall weight of the rifle.

Heavy-contour barrels are typically seen on target rifles or benchrest rifles. This is because they have significantly more weight due to the thickness of the barrel. There are a few different profiles or contours within this category of barrels, such as Bull barrels and Varmint barrels. These barrels heat up the slowest compared to lightweight and medium-contour barrels, which makes them ideal for target shooting where the shooter will be taking multiple shots but doesn’t plan to move much.

What Does a Fluted Barrel Do for a Rifle?

There are certain barrel designs that provide a middle ground between having a medium or heavy profile and maintaining a lighter barrel; this is called fluting. Fluting is a process in which a medium or heavy-profile barrel has channels cut on the outside of the barrel. These grooves provide more surface area to allow for faster heat dissipation, as well as cutting down on the weight of the barrel. The fluting is either cut in straight lines or in a spiral motion down the barrel, keeping even spacing between each channel. This is important for allowing the barrel strength to remain intact and not having a weak spot caused by the fluting.

Choosing the Best Rifle or AR15 Barrel

There are many different aspects to the barrel-making process, and each has its own impact on performance. Generally, there is a tradeoff between weight, longevity, accuracy, and cost. The barrel type you choose will depend on the purpose of your rifle as well as your budget. Learn more in our other Rifle Barrel Guides from more in-house experts and enthusiasts!

There are many different aspects to the barrel-making process, and each has its own impact on performance. Generally, there is a tradeoff between weight, longevity, accuracy, and cost. The barrel type you choose will depend on the purpose of your rifle as well as your budget. Learn more in our other Rifle Barrel Guides from more in-house experts and enthusiasts!

Browse from top brands like Ruger, Remington, Winchester, and more right here at OpticsPlanet!

If you’re looking for ammo, we have plenty in stock and ready to ship today!